How to keep farm equipment at peak performance during harvest

Harvest is in full swing here in northwest Iowa and the many farmers and farm workers are spending long hours working hard to provide for not only their families, but also the rest of the country and its many industries that rely on agriculture.

Harvest is a critical period of the year for obvious reasons. A strong harvest is critical to a farm operation’s finances and a lot can go right or wrong that will influence how successful harvest is for each farm operation.

One of the primary concerns of any farmerfarm worker this time of year is making sure all farm equipment and machinery is in good working condition. Now’s not exactly the most opportune time for failures and long, costly repairs.

That’s why it is important to make sure farm equipment maintenance schedules have been followed up to this point and that proper care is being taken during the harvest period itself to keep every piece of equipment running properly.

Harvest suffers when equipment maintenance isn’t a priority

Not following proper scheduled maintenance on farm equipment is asking for untimely breakdowns and costly repairs. Those repairs are going to hit the equipment owners in the wallet when they happen – and could be even more costly if that time falls around harvest.

Don’t neglect maintenance on equipment and you can avoid these emergency repairs and machinery failures that only end up cutting into the bottom line. It’s best to follow and keep up on maintenance schedules and to identify the minor issues before they evolve into major problems.

Ignore this advice and your entire harvest schedule could be thrown into a serious lurch.

Proactive, preventative farm machinery maintenance

Luckily, there are several ways farmers can prevent as many unexpected repairs and machinery failures as possible. There are also good practices and habits that can help equipment owners and operators make sure their equipment remains in good condition throughout harvest, too.

In this blog post, we’ve collected pointers that will help keep your harvest schedule on track by taking care of farm equipment and machinery.

Don’t fall behind on maintenance

One of the surest ways to experience equipment failure and spend money on expensive repairs – as if that’s something you’d ever want to do – is to forgo a regular maintenance routine and not follow typical maintenance schedules.

It’s important to keep on top of any kind of farm maintenance, including equipment and machinery. Keep equipment clean, store it properly away from the elements and harsh weather, and inspect equipment before and after use.

Because many pieces of equipment can be put under a lot of demand during harvest, including combines, it’s important to regularly check that all equipment and parts of these machines are in working order.

If you notice small repairs that need to be made, then it’s a good idea to address those and get the work done before those problems grow into much more serious – and much more expensive – issues. This is especially true during harvest, as a few days lost here and there can be the difference between a serious time crunch as cold weather approaches and, in a worst case scenario, crop is lost.

Develop a maintenance schedule – and stick to it

If you or your tenant farmer do not yet have a consistent maintenance schedule for all of your equipment, then now is the time to develop that. Remember: preventative maintenance is often the best kind of maintenance.

Hopefully, equipment checks and preventative maintenance were performed before harvest began, but now is the time to make sure that regular checks and maintenance are performed. Again, we cannot stress enough that now is the time to take care of your equipment, an incredibly valuable asset, before breakdowns and failures cost you time and money.

To begin following a maintenance schedule, you need to create an inventory of the equipment you have. Then, determine which equipment you will check and perform minor repairs on for any given day. This way, you hopefully will be able to discover more serious repairs needed and not be caught off guard.

Maintenance to perform on machinery

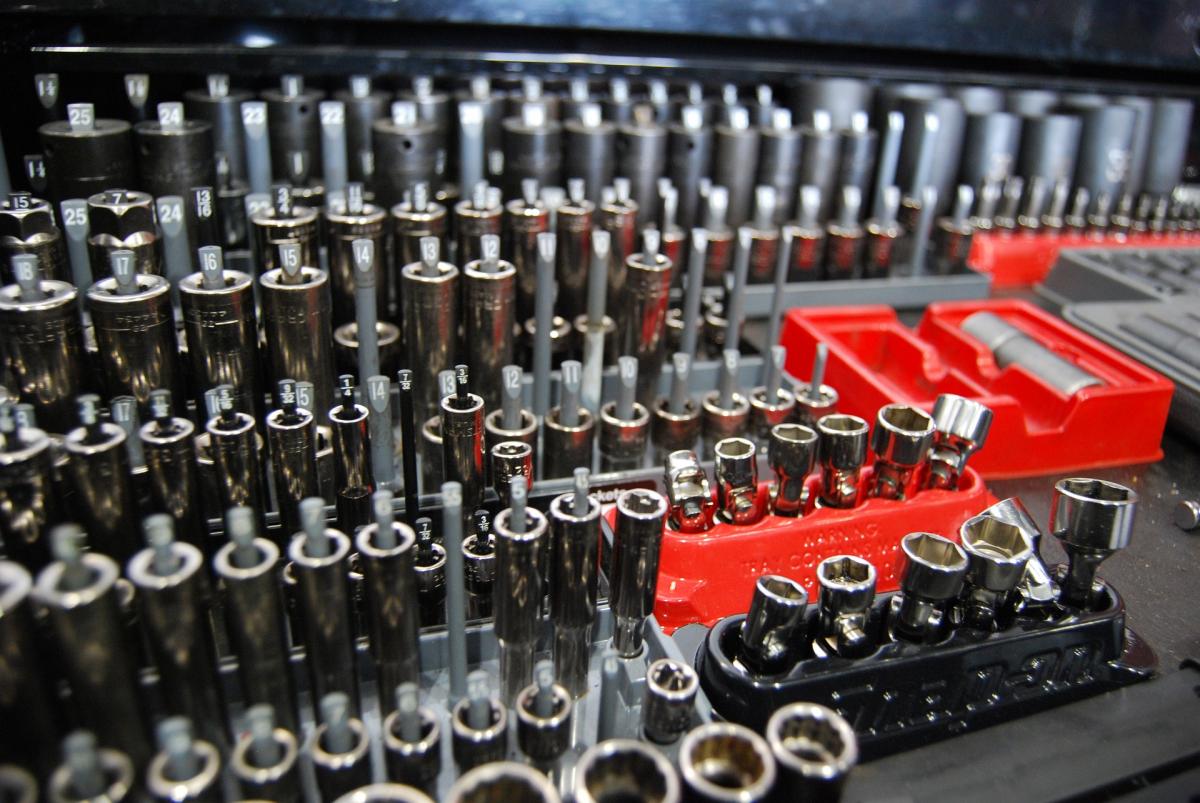

What sort of maintenance should you be performing on machinery? Well, there are several things farmers can do themselves to keep equipment running smoothly and efficiently.

This includes:

- Checking and changing engine oil, transmission fluid, coolants and hydraulic fluid

- Lubricating moving parts on machinery

- Keeping an eye on and changing oil and air filters

- Checking bearings and anything that rotates and lubricating when needed

- Inspecting for any general damage that requires attention

Inspect equipment before operation

Always inspect machinery before you or anyone else begins operating it. This is a good tip any time of year around farm equipment, but it’s specifically important during this harvest season.

Walk around the equipment for a visual check. Inspect the engine and any moving parts, especially if they may have been showing signs of wear and tear. They’re being run pretty hard, after all.

Order parts ahead of time

If you have any reason to suspect you may need them, now is the time to order replacement parts. These may take time to reach you, so it’s better to be proactive and have them delivered and on hand when you don’t quite need them, than to be scrambling or driving long distances to pick up parts several counties over.

One useful tip is to recall the previous year’s harvest and take note of any part failures that occurred then. It’s a good way to create a list of parts that you may want to order ahead of time this year.

Cotton Grave can help manage your farm

Harvest comes down to protecting your bottom line. Equipment upkeep is just one small part of that.

Cotton Grave Farm Management can help manage your entire operation from every aspect, including marketing, finances, cash rent management, tenant selection and so much more. Our team is among the most experienced and trusted in northwest Iowa and is always ready to help discuss your goals for the future.

Contact us today to learn more about the services we offer.

Read Our Other Articles